9 Easy Facts About American Plastics Shown

Table of ContentsAll about American PlasticsHow American Plastics can Save You Time, Stress, and Money.Fascination About American PlasticsAmerican Plastics for BeginnersOur American Plastics Ideas

A little research can aid you over time. It is challenging to judge its top quality initially look with the look of HDPE pipeline installation, many defects are revealed when utilizing, so we can just have a correct judgment after usage. It is essential to select HDPE pipeline installations made by a specialist producer with a great credibility and reputation.

A technological specialist is crucial for an excellent product, specifically in the manufacturing industry, due to the fact that a little error will certainly result in the failing of the whole project. HDPE pipelines can change concrete pipelines in area systems to save time and expense of fixing busted or ruptured pipes. HDPE pipeline is likewise a more economical choice contrasted to various other piping materials in regards to operating and installation costs.

Some Of American Plastics

HDPE pipes are manufactured with solid straight or bent sections. It is made of lightweight products that are easy to transport and does not call for hefty setup tools such as heavy cranes. The mix of lightweight and adaptable structures makes it perfect for earthquake-prone locations. The pipelines are not weak and can be quickly placed right into a bent area without extra jointing or welding.

Chemicals immune to HDPE pipes can infect the pipeline. The pipeline does not function with chemicals and does not melt warm or electrical power.

HDPE pipes are normally solid and resistant to damage triggered by external lots, high stress or vibration - https://www.quora.com/profile/Dane-Coffman-3. The pipes can hold up against handling and bend also in chilly weather condition. Safe eye liner HDPE internal tubes Smooth Line Pipe Moving lining making use of roller mixes Pipeline explosion Plastic plumbing systems Building of new pipelines Rust resistance, no dripping, high longevity

Warmth integration, while its obstacles exist, can produce solid and reputable joints. Solutions: The stamina and toughness of HDPE can be determined by its capability to hold up against temperature levels of around 248F in the short-term or even a consistent 230F. If your application includes gas and fluid to gain access to and elevate those temperatures, HPDE piping is a reputable remedy.

A Biased View of American Plastics

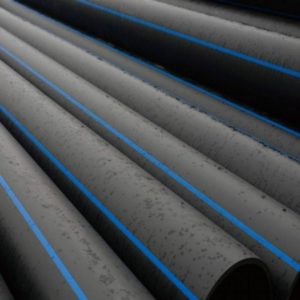

A drinkable water line/potable water pipeline is always dark with blue red stripes and pipes passing via fluids, fluids under pressure, and process gases are always filled with a yellow or black jacket with yellow lines. HDPE pipeline material have been Read Full Report used in the general market for over half a century and their outcomes are amazing, constructing self-confidence among manufacturers that they are a lot more concentrated on HDPE pipe remedies.

Times since 1991 Elimination of material demands with gauge and modification. In the tension fracture resistance examination the cellular division requirements were weakened. It is practical to conclude that HDPE pipe built today might have.

Each size group is created bearing in mind the needs of pressure, flow price, and ecological variables of the intended application. By matching the appropriate HDPE pipeline size to its usage, engineers and service providers can maximize performance and expand the life-span of their piping systems. Measurement and size are related principles in the context of HDPE pipelines.

All about American Plastics

As stated earlier, pipelines with reduced SDR values have the ability to hold up against higher stress, which is an essential consideration in the selection procedure for jobs that entail high pressure or essential applications. hdpe pipe supplier in Texas. Choosing a pipe with an unsuitable SDR might cause system failing, safety threats, and expensive repair work. Choosing the proper HDPE pipeline size is critical for the success and performance of any type of piping system

Application Specifics: Customize your pipe size choice to the specific needs of its application, whether for local, commercial, or various other usages. Recognizing exactly how the HDPE pipe will be used, the anticipated circulation rates and the stress demands are essential. High-pressure applications may need a pipeline with a better wall density to hold up against the inner tensions, while a lower-pressure, high-flow system could prioritize diameter size to reduce rubbing loss.

All about American Plastics

Comply with these steps: Examine the Application: Determine the pipeline's meant use, consisting of environmental variables and service problems. Refer to SDR: Examine the common measurement proportion to locate a pipe that can deal with the necessary stress.

Choosing the ideal HDPE pipeline dimension is a delicate equilibrium in between many technical specs and sensible demands - https://www.twitch.tv/americanplastic/about. With cautious consideration and precise computations, you can ensure the dimension of the pipe you choose will certainly offer your demands efficiently and efficiently. Selecting the right HDPE pipe dimension is vital for system performance, durability, and cost-effectiveness

Understanding these facets will ensure optimal performance and compatibility throughout your piping system - hdpe pipe suppliers Midland TX. The awaited circulation rate or volume of the liquid being transferred is one of the main factors in pipe size option. A pipe that is as well tiny can limit flow, causing pressure loss and possible clogs, while an extremely big pipeline might cause unnecessary expense and minimized system performance