The Greatest Guide To American Plastics

Table of Contents4 Easy Facts About American Plastics DescribedFascination About American PlasticsNot known Factual Statements About American Plastics The smart Trick of American Plastics That Nobody is DiscussingEverything about American Plastics

Bigger projects might require pipelines with better diameters to efficiently distribute fluids over long distances. Elements such as terrain difficulty, the possibility for ecological stress and anxiety, and the setup atmosphere must affect the pipe dimension to make sure an effective, enduring application.

Involve with specialist recommendations to verify your option and adapt as required for ideal results. Equipped with this knowledge and the workable actions laid out, you are fully equipped to make informed decisions when picking HDPE pipe sizes for your projects. Your interest to information in this selection process will go a long way in ensuring the effectiveness, safety, and cost-effectiveness of your piping systems.

The Facts About American Plastics Revealed

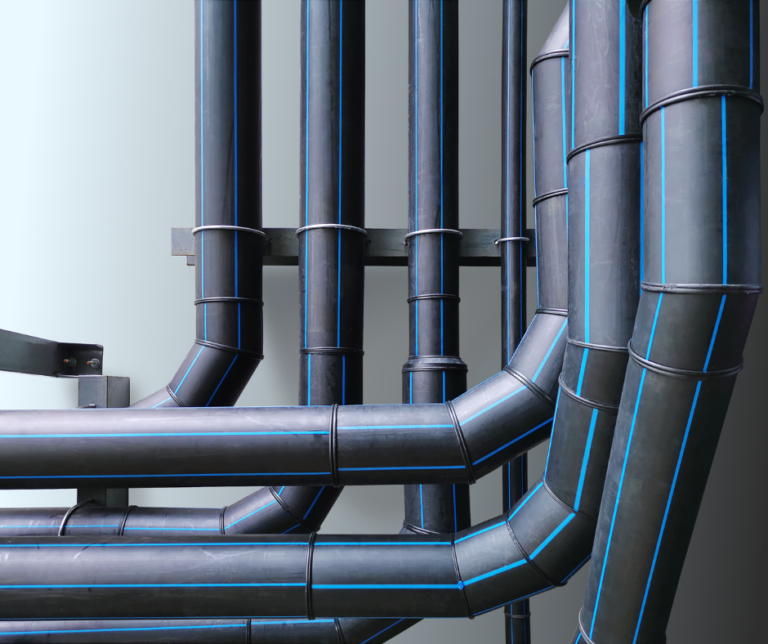

HDPE pipes are extensively taken on throughout an array of fields due to their flexibility and strength. One of the most common usages for HDPE pipeline is in water supply systems.

: HDPE pipelines are joined via warm combination, developing a seamless, homogenous link as solid as the pipeline itself. This watertight joint is critical in gas and water circulation, where leakages can cause harmful scenarios or pricey waste.: HDPE pipes are lighter than conventional steel pipelines, making them simpler to deliver and mount.

Our straightforward and fast buying procedure and efficient logistics ensure you get your 4-inch HDPE pipeline in the shortest feasible time (HDPE Pipe for Oilfield). Our after-sales team is readily available 24/7 to help with any kind of issues you may come across, ensuring peace of mind.

PE 80 is for easy industrial applications like gas and water, while PE 100 supplies long-term stamina and efficiency for tougher uses. For a concise consider applications, below are several of one of the most usual kinds of HDPE piping and their applications. Piping systems make use of PE 32 or PE 40 for low-pressure applications.

American Plastics for Dummies

PE 80 has a material immune to fractures, so it appropriates in applications vulnerable to cracking, like sewer system and water distribution lines. PE 100 is additionally resistant to cracks, and 100 N/mm2 is the minimum needed stamina. As discussed, categories of HDPE piping consist of nominal stress, material, and color coding.

Makers produce pipelines with different stress qualities (PN qualities). This shows the pressure in bars the pipe can support with water at 68 degrees Fahrenheit. The pressure grades comply with European criteria, and they are: PN 2.5 max pressure 2.5 bar PN 4max stress 4 bar PN 6max stress 6 bar PN 10max stress 10 bar PN 16max stress 16 bar The shade codes that indicate the stress grade are yellow for PN4, red for PN6, blue for PN10, and green for PN16.

Pipeline suppliers supply sizing overviews with additional information like wall thickness and mass. Quality control adheres to ISO criteria managing the product design and minimum needed stamina (MRS) of pipes.

Industries think about nominal stress, product, and other parts when determining which pipes to make use of - hdpe pipe supplier in Texas. Today, you'll see high-density polyethylene pipelines in supply of water, gas distribution, agriculture, and far more. Industries utilize PN 10 grade HDPE pipeline for water supply and distribution networks. You'll generally see it in multistory apartment complicateds.

Fascination About American Plastics

It's worth keeping in mind that gas needs high tolerance to pressure, making PN-16 to PN-2 quality pipelines appropriate for procedures. The farming market uses HDPE pipelines for irrigation and drainage.

Mining companies utilize pipes for slurry transport and dewatering. HDPE piping can secure cords in the telecom industry. This is beneficial for below ground cables. The most effective part is that services can make use of general PN course pipelines for this application. Industries select HDPE piping over traditional pipes due to the fact that they offer much more advantages.

For starters, HDPE pipelines are extremely long lasting and can last a lengthy time with very little maintenance. They're also resistant to rust, chemicals, and UV rays. https://freeseolink.org/American-Plastics_386503.html. HDPE pipelines are likewise affordable compared to other piping materials. They're much less susceptible to damage, which reduces repair service expenses! HDPE pipes are lighter than typical pipelines for far better handling and transportation.

Some Ideas on American Plastics You Should Know

Whether you're click to find out more a service provider, designer, or DIY enthusiast, this write-up will certainly provide you with the knowledge to make informed choices and accomplish ideal results. When it comes to selecting the right HDPE pipe for your task, understanding the PSI rating is of utmost value. The PSI score measures the strength and pressure capacity of the pipeline, showing just how much stress it can withstand without failure.

The PSI rating of an HDPE pipe determines its capability to handle various stress levels. Pipes with higher PSI scores can withstand better pressure, making them ideal for applications that entail higher fluid or gas stress. On the other hand, pipes with reduced PSI ratings are optimal for low-pressure applications.