The Value of an Optical Measurement System in Industrial Applications

Optical measurement systems play a crucial duty in industrial applications. They supply high precision and assist in non-contact measurement, which is important for protecting sensitive parts. These systems enhance operational effectiveness and advertise quality control. Their application is not without obstacles. Understanding their relevance and the intricacies entailed can illuminate their transformative possibility in modern-day manufacturing. What are the specific advantages and challenges that these systems existing?

Comprehending Optical Measurement Equipments

Optical measurement systems play an essential role in numerous commercial applications by supplying exact and exact information collection. These systems make use of light to measure physical properties such as dimensions, surface accounts, and material characteristics. The essential elements normally consist of lasers, electronic cameras, and sensors that capture and evaluate light shown from objects. By using techniques such as interferometry and photogrammetry, these systems can identify minute changes fit and dimension, which are critical for quality assurance and item consistency.Furthermore, optical measurement systems are non-contact, allowing them to examine delicate or complex things without causing damage. They are flexible, locating applications in areas like aerospace, automobile, and electronic devices manufacturing. The combination of sophisticated software application for information analysis enhances the capability of these systems, enabling real-time tracking and comments. As sectors evolve, the importance of optical measurement systems remains to grow, supporting the need for greater accuracy and performance.

Key Benefits of Optical Measurement in Production

While standard measurement methods commonly include physical get in touch with and can present mistakes, the fostering of optical measurement systems in producing deals significant benefits. These systems use non-contact techniques, minimizing the threat of damage to delicate elements and guaranteeing the integrity of dimensions. Optical measurement provides high accuracy and accuracy, allowing producers to achieve tight tolerances essential in competitive markets.Additionally, the speed of optical measurement systems boosts productivity. optical measurement system. Quick information purchase permits real-time surveillance, promoting instant adjustments in production procedures. This effectiveness results in reduced waste and boosted source allocation.Furthermore, the adaptability of optical systems fits a broad variety of materials and geometries, making them appropriate for numerous applications. Their capacity to integrate perfectly with automation technologies supports Sector 4.0 initiatives, advertising smarter making environments. In general, the crucial advantages of optical measurement add significantly to improving quality assurance and operational efficiency in contemporary production settings

Applications of Optical Measurement Systems

Optical measurement systems play a crucial role in different industrial applications, specifically in improving accuracy during making processes. They are important to quality control and guarantee, guaranteeing that items meet rigid standards. Furthermore, these systems sustain r & d initiatives by supplying accurate data for advancement and renovation.

Precision in Production Processes

In modern manufacturing, high accuracy is necessary for guaranteeing item quality and operational performance. Optical measurement systems supply sophisticated abilities that significantly improve precision during the production process. These systems utilize light and imaging technologies to catch comprehensive measurements of components, enabling manufacturers to achieve tight tolerances and exact measurements. By integrating optical measurement into manufacturing workflows, companies can rapidly determine variances from requirements, therefore reducing waste and minimizing rework. In addition, the non-contact nature of optical measurements permits inspecting delicate or sensitive products without threat of damages. Inevitably, the fostering of optical measurement systems promotes a culture of accuracy in manufacturing, leading to boosted performance and competition in the marketplace.

Top Quality Control and Assurance

Quality guarantee in producing greatly counts on specific measurement methods to ensure that products meet established criteria. Optical measurement systems play an essential function in this procedure, making it possible for precise assessments of dimensions, surface area top quality, and other critical features of manufactured items. By using high-resolution imaging and innovative analysis algorithms, these systems discover discrepancies from specifications, making certain consistency throughout production. Furthermore, optical measurements can be non-destructive, protecting the integrity of items while helping with quick evaluations. The assimilation of these systems into top quality control protocols boosts efficiency and minimizes waste, inevitably contributing to boosted product dependability. As markets undertaking for quality, the fostering of optical measurement modern technologies ends up being increasingly necessary for keeping affordable benefit and consumer complete satisfaction.

Research Study and Development Applications

As industries undertaking for development, optical measurement systems have emerged as a necessary device in research study and growth applications. robotic vision. These advanced systems offer accurate measurements of materials and elements, allowing engineers and scientists to gain crucial insights right into their properties and why not try here efficiency. Optical measurement technologies, such as laser scanning and interferometry, promote the quick prototyping of new designs and the optimization of existing items. By recording high-resolution information, researchers can identify issues and examine the effect of various parameters on product functionality. Furthermore, these systems sustain interdisciplinary cooperation, connecting gaps in between different fields of research. The combination of optical measurement systems into R&D refines inevitably speeds up development timelines and cultivates the development of advanced solutions in various commercial industries

Contrasting Optical Measurement to Traditional Techniques

In contrasting optical measurement systems to traditional approaches, several essential elements emerge, consisting of precision and precision. In addition, the speed of measurement and cost-effectiveness play substantial functions in establishing the suitability of each strategy for industrial applications. This examination highlights just how improvements in optical technology might offer benefits over standard strategies.

Accuracy and Accuracy

Optical measurement systems offer significant benefits in precision and precision contrasted to typical measurement techniques. These systems utilize sophisticated innovation, such as lasers and high-resolution cams, to record dimensional data with minimal error. In contrast, conventional techniques commonly count on mechanical devices that can introduce variability due to human error or product wear. Optical systems can attain micrometer-level accuracy, making certain regular results even in complicated geometries. In addition, they supply non-contact measurement, lowering the risk of damaging sensitive components. This capacity is specifically beneficial in industries where tolerances are important, such as aerospace and auto manufacturing. The adoption of optical measurement technology improves high quality control and minimizes the chance of issues, eventually boosting total production effectiveness.

Speed of Measurement

The benefits of optical measurement systems prolong beyond accuracy and accuracy to include substantial enhancements in measurement speed. Typical measurement approaches usually call for extensive arrangements and hand-operated computations, which can slow down production procedures. On the other hand, optical systems use innovative innovations such as laser scanning and imaging, enabling fast data procurement and processing. This efficiency permits for real-time measurements, promoting quicker decision-making in producing settings. The capability to record big volumes of data quickly improves throughput and productivity, giving organizations an one-upmanship. Additionally, with lowered measurement times, optical systems minimize downtime linked with evaluations, additionally streamlining procedures. As a result, the speed of measurement in optical systems substantially contributes to general functional efficiency in commercial applications.

Cost-Effectiveness Evaluation

A comprehensive cost-effectiveness analysis exposes that optical measurement systems usually provide considerable monetary benefits over traditional methods. These systems usually minimize the demand for considerable physical setups, minimizing labor costs and downtime throughout measurement processes. Optical approaches can additionally produce faster results, bring about raised performance and minimized functional expenses. Furthermore, the precision supplied by optical dimensions decreases the chance of costly errors, which can occur from hands-on treatments and standard strategies. In the long run, the initial financial investment in optical innovation is commonly balanced out by cost savings in resources, time, and enhanced item high quality. Markets that take on optical measurement systems might locate themselves not just improving efficiency however also attaining a much more favorable cost-benefit proportion compared to standard approaches.

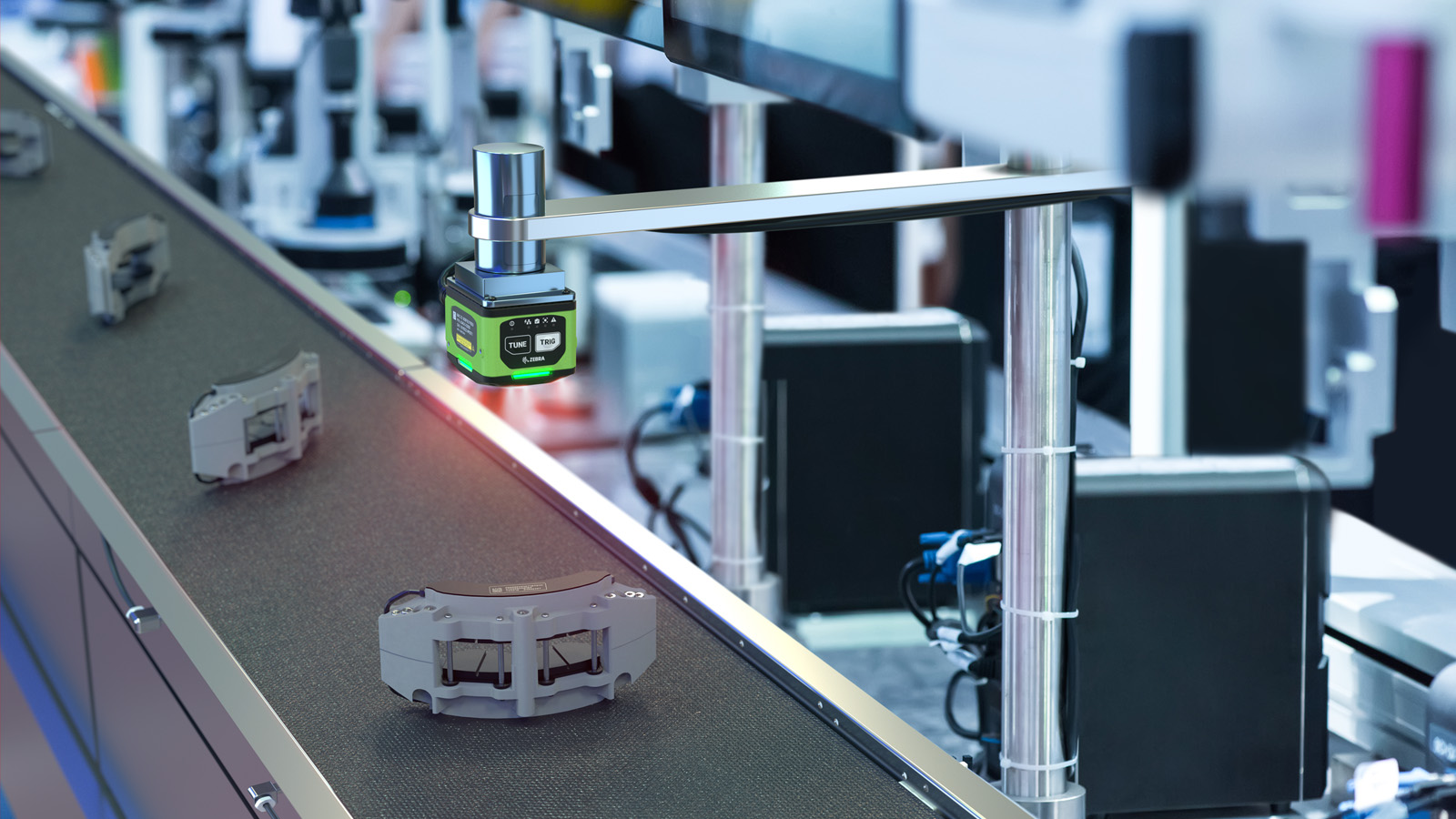

The Role of Automation in Optical Measurement

While numerous sectors progressively rely on precision and performance, automation has arised as a critical part in enhancing optical measurement processes. By integrating automated systems, companies can considerably enhance measurement accuracy and decrease human error. Automated optical measurement systems make use of sophisticated algorithms and sensing units to give real-time data evaluation, promoting quicker decision-making and process adjustments.Additionally, automation enables consistent measurements throughout different manufacturing runs, making certain that quality standards are kept. The scalability of automated optical measurement systems makes them ideal for diverse applications, from high quality control in making to evaluation in semiconductor production.Furthermore, these systems can be effortlessly incorporated into existing manufacturing configurations, advertising a smooth change towards much more reliable procedures. Overall, the function of automation visite site in optical measurement is essential, supplying enhanced reliability, decreased labor expenses, and enhanced functional performance, inevitably driving commercial competition.

Obstacles and Factors To Consider in Execution

Carrying out optical measurement systems, despite the advantages of automation, provides different obstacles and considerations that organizations need to navigate. One significant difficulty is the integration of these systems into existing operations, which may call for considerable changes in procedures and staff member training. Organizations needs to likewise deal with the compatibility of optical measurement innovations with existing devices and software.Additionally, the variability of products and ecological conditions can affect measurement precision, requiring robust calibration and maintenance methods. Cost is another important consideration, as first financial investments can be considerable, and organizations have to consider these expenses against possible effectiveness gains. Data monitoring likewise presents difficulties, as the volume of information produced requires reliable systems for storage space, evaluation, and interpretation. Making certain compliance with sector requirements and regulations adds one more layer of intricacy to the execution procedure, requiring mindful planning and implementation.

Future Trends in Optical Measurement Technology

As markets continue to advance, developments in optical measurement innovation are established to transform their functional landscapes. Arising trends suggest a change towards boosted automation and assimilation with synthetic intelligence, boosting the accuracy and effectiveness of measurements. Flexible optics is gaining traction, enabling systems to readjust in real-time to differing environmental problems, thereby lessening mistakes. The miniaturization of optical sensors is enabling their implementation in a lot more compact and diverse settings, expanding application chances in industries such as aerospace and manufacturing.Additionally, the advancement of 3D optical measurement techniques is revolutionizing high quality control procedures, offering more considerable information analysis. Developments in data processing formulas are additionally expected to enhance the analysis of complicated dimensions, making insights extra obtainable. Collectively, these patterns show a future where optical measurement technology not just boosts accuracy however likewise improves operational dexterity, positioning industries to better satisfy progressing needs.

Often Asked Questions

Just How Do Optical Measurement Solutions Ensure Data Accuracy?

Optical measurement systems guarantee data precision through accurate calibration, progressed formulas, and high-resolution imaging. These elements function together to decrease errors, enhance measurement uniformity, and offer reliable results necessary for different industrial applications and processes.

What Is the Normal Life Expectancy of an Optical Measurement System?

The normal life expectancy of an optical measurement the original source system varies, typically varying from five to fifteen years. Variables affecting longevity include use intensity, ecological problems, upkeep practices, and technical improvements that might demand upgrades or substitutes.

Can Optical Measurement Equipments Be Personalized for Certain Industries?

What Training Is Required for Running Optical Measurement Equipments?

Training for running optical measurement systems normally includes understanding system components, software use, calibration methods, data evaluation, and security protocols. Individuals often participate in hands-on technique and may finish qualification training courses to improve their effectiveness.

Just How Do Ecological Variables Affect Optical Measurement Results?

Environmental factors, such as temperature level, humidity, and lights conditions, substantially affect optical measurement outcomes. Variants in these elements can lead to inaccuracies, influencing the accuracy and integrity of dimensions taken by optical systems in various settings.